After careful selection of individual qualities in the countries of origin, raw coffee beans arrive at our plant inside big bags for coffee processing. Thus begins the delicate coffee roasting process distinguished in 4 stages, from cleaning and sectioning the coffee to its packaging.

Raw coffee cleaning and sorting

The first stage is Raw Coffee Cleaning and Sorting. Beans are discharged into the pit and transferred to the cleaning machine called Tarara. Coffee processing and production continues with the raw coffee beans selected and cleaned of impurities and waste. Next, the raw coffee is poured inside the “Spietratrice”, a machine designed to remove foreign materials. The last stage of this important phase is Optical Sorting, by which all beans of undesirable colour are identified according to analytical parameters. This is a stage in which state-of-the-art instruments are applied in order to achieve excellent results.

Roasting

The second stage of coffee production is Roasting, a fundamental and delicate process that requires the knowledge, precision and passion of experienced professionals. Each quality of raw coffee in fact has its own peculiarities, related to the plantation of origin. For this reason, we perform a customized, single-origin roasting of raw coffee, which aims to enhance and exalt its organoleptic characteristics. A sort of coffee identity card is thus defined. The final moment of this phase is the air cooling process, in special tanks containing 4 rotary arms.

Coffee Blending

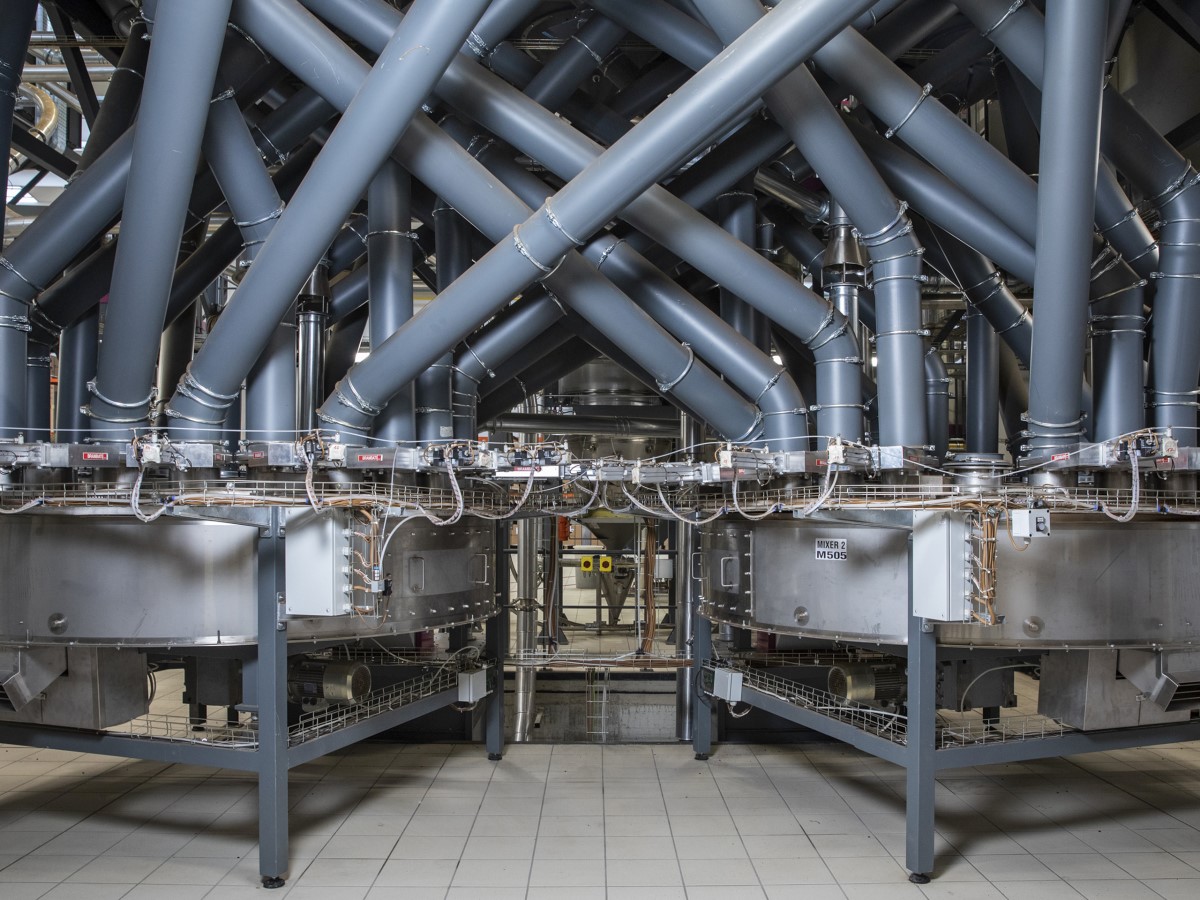

The third phase consists of Coffee Blending. The perfect union of different coffee varieties is a real art that allows guaranteeing over time all the organoleptic characteristics that distinguish Portioli’s blends.

Thanks to a careful selection of different single-origin coffees from different countries and single-origin roasting of raw coffee, we arrive at the important blending process based on expertly designed and balanced recipes. Through sample tastings by our staff of specialized tasters, the characteristics of each product such as aromas, body and flavours are analysed and therefore delineated.

Our recipes are then processed and analysed periodically through sample testing to arrive at the best in-cup result.

Coffee Packaging – Final stage in the production

The last phase consists of Coffee Packaging. Blended coffee is transferred to the storage silo, and then to the rotary one that separates the intact and whole coffee beans, from the broken ones. Once this step is completed, the selected and roasted coffee is poured into the multiple packaging machines, which according to precise production schedules will make different formats, suitable for all uses. The packaged coffee is ready to be shipped.

Storage is done in a cool and airy place to best preserve the organoleptic characteristics of the different blends.

The entire Portioli’s coffee production cycle takes place inside our factory. This allows us to carefully and attentively follow every single production phase from the entry of the raw coffee to the shipment of the packaged product, always guaranteeing the high quality of our blends on the market.